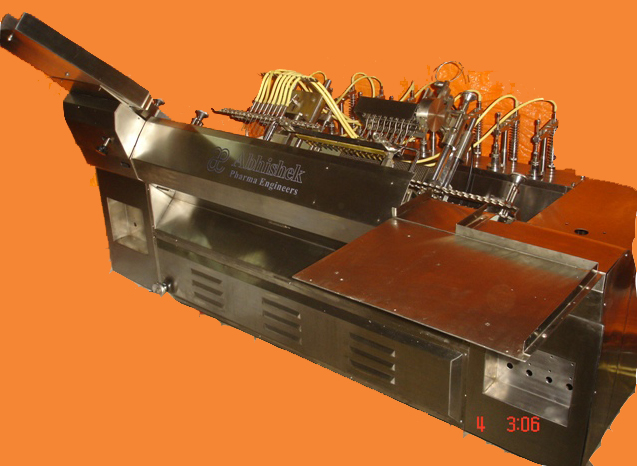

ABHISHEK PHARMA ENGINEERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ABHISHEK PHARMA ENGINEERS

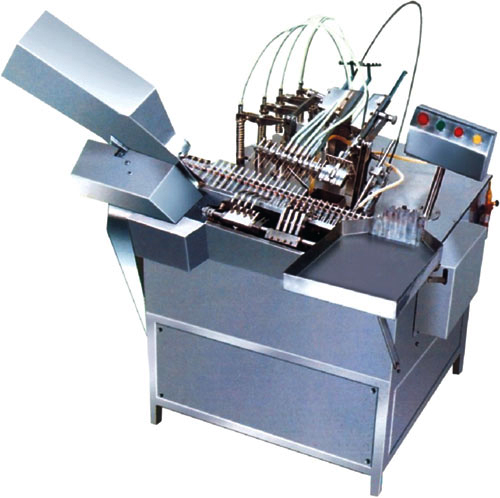

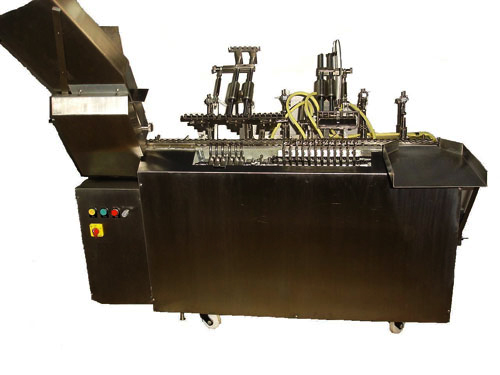

Four Stroke Filling Sealing Machine

our Stroke Ampoule Filling Sealing Machine built on principle of slant travel of ampoules while filling and sealing, to take care of vide variation of ampoule neck dimensions, thicknesses of available standard ampoules.

Features

» Compact GMP model

»Production output ranging from 30 ampoules/minute to 150 ampoules/minute

» All contact parts made from AISI SS 316L & other Non-contact parts made from AISI SS 304.

» Machine is suitable to fill 1ml to 20ml ampoules and minimum change over parts from 1ml to 20ml ampoule size

» Ampoule neck centering during gas flushing and filling operations

» Possibility of nitrogen gas flushing before, during and after filling

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.